Searching for trusted Mississauga tile installation specialists? Work with a local expert who comprehends city permits, condo/HOA rules, and GTA freeze‑thaw impacts. Insist on quality standard conformity, water protection, proper underlayments, and control joints. Require itemized quotes, professional-grade mortars, proper water protection, and clean jobsites. Verify Ontario licenses, WSIB, protection policies, and protection agreements. Assess matching estimates and connect payment to completion stages. You'll learn to select materials, layouts, and schedules that satisfy inspection standards.

Core Insights

- Regional specialists knowledgeable in local regulations, homeowner association requirements, required documentation, and how GTA weather affects building substrates and freeze-thaw cycles.

- We hold Ontario licenses, WSIB protection, complete liability insurance, and validated references with physical craftsmanship reviews.

- Written project proposals aligned with TTMAC/TCNA standards, including substrate prep, waterproofing systems, expansion joints, and warranty specifications.

- Proven quality assurance includes moisture level checks, surface contour analysis, anti-fracture or uncoupling membrane installation, and standard-compliant water protection for water-exposed zones.

- Clear payment schedules with milestone-based billing, with matching estimates, dust control plans, and comprehensive maintenance records.

Why Choose Local Tile Specialists in Mississauga

Cut through guesswork by hiring local tile specialists who are familiar with Mississauga's building regulations, permit requirements, and weather impacts on base materials. You receive code-compliant installations, accurate moisture management, and correct underlayment selection for seasonal changes. Local pros leverage area experience to locate verified materials, coordinate inspections, and work with municipal inspectors. They understand slab flatness tolerances, expansion joints, and anti-fracture membranes appropriate for GTA specifications.

You also gain a proven neighborhood reputation. It's possible to verify references in the area, inspect in-person workmanship, and verify warranty responsiveness. Local contractors emphasize organized site operations, dust management, and secure entry in dense urban settings. They offer transparent costs, synchronize timelines with condo and HOA rules, and detail project details, substrate prep, and installation materials. This attention to detail secures your investment and ensures long-lasting, up-to-code results.

Services We Offer: Tile Installation Solutions

Utilizing local code knowledge functioning in your favor, you can choose targeted tile services that suit your spatial and functional needs. For kitchen backsplashes, you receive clean substrate preparation, laser layout, tight joints, and grout sealing that streamlines maintenance. In bathrooms, we set up code-compliant waterproofing, slope-to-drain pans, humidity regulation, and expansion joints, then conclude with eco friendly adhesives and low-VOC grouts. On floors, we analyze deflection, apply crack prevention membranes or uncoupling systems, and position tiles with exact trowel patterns for optimal flatness and durability.

We specialize in constructing feature walls that adhere to safety standards, mounting criteria, and structural demands, carefully including niches and lighting cutouts with exacting tolerances. We provide clear project scopes, dependable timeframes, and documented warranties, ensuring your tiled surfaces look stunning and perform optimally for years into the future.

Choosing the Perfect Tile Materials for Your Area

Although visual appeal matters, it's essential to pick tile by matching physical attributes to intended use, traffic load, and moisture conditions. In wet areas, select porcelain with minimal moisture absorption (≤0.5%) and slip resistance values per ANSI A326.3. In heavily trafficked areas, choose PEI 4-5 wear ratings and rectified edges for narrow grout joints. Natural stone requires appropriate sealing of pores and deflection checks (L/720 for stone assemblies). For kitchen applications, choose stain-resistant glazed porcelain; for shower installations, confirm waterproofing with ANSI A118.10 membranes.

For sustainable flooring choices, consider environmentally conscious ceramics with recycled content and environmentally safe adhesives. For those implementing radiant floor heating, verify your materials are rated for heated floor systems, incorporate uncoupling membranes, and follow proper thermostat sensor placement guidelines. Make sure to align your grout type and joint width with movement control joints as specified in TCNA EJ171.

Design Options and Customization Guide

We'll provide professional recommendations on material and finish selection that matches performance ratings, slip-resistance requirements, and upkeep objectives. We'll recommend layout patterns and accent designs that control sightlines, optimize material usage, and satisfy expansion joint criteria. We'll work together to complete a specification that balances aesthetics, longevity, and code compliance.

Materials and Finishes Guide

Prior to picking tile, it's essential to establish the area's practical needs and design intent, then match surface options to these requirements. For wet areas, select porcelain with low water absorption and a DCOF ≥ 0.42 for slip resistance. For light-duty walls, ceramic tile works well; for high-traffic areas, look into sintered stone or quarry tile. Be sure to confirm the cold-resistance rating for outdoor installations and stain resistance for pools and kitchen spaces.

Select finish by intended use: matte finish where traction is needed, honed surfaces to reduce reflections, polished finish exclusively for dry interior spaces. Coordinate grout colorways to control appearance and seam appearance. Select sustainable sealant options and low-VOC installation materials to meet air quality requirements. Check depth requirements, deviation allowances, and squared edges for tight seams. Confirm products meet ANSI, TCNA, and local building codes.

Pattern Layouts and Decorative Accents

When tile choices are finalized, develop a layout plan that harmonizes with room dimensions, movement paths, and upkeep needs. Running-bond, diagonal, and square-grid arrangements affect aesthetic appeal, anti-slip properties, and grout upkeep. Utilize a centered control line and preliminary placement to ensure symmetry, cutting locations, and entryway spacing. Place grout joints to prevent thin pieces at borders; ensure consistent joint widths following ANSI A108 and TCNA specifications.

Introduce herringbone accents to delineate focal areas or transition areas without disrupting egress paths. Specify contrast borders to frame cooking, bathing, or fireplace areas, ensuring movement joints at edges and every 20-25 feet in interiors. Assess tile consistency and tone before installation. Level thresholds with finished floor heights, add schluter profiles for neat terminations, and grade wet zones to compliant drains.

Quality Standards and Installation Process

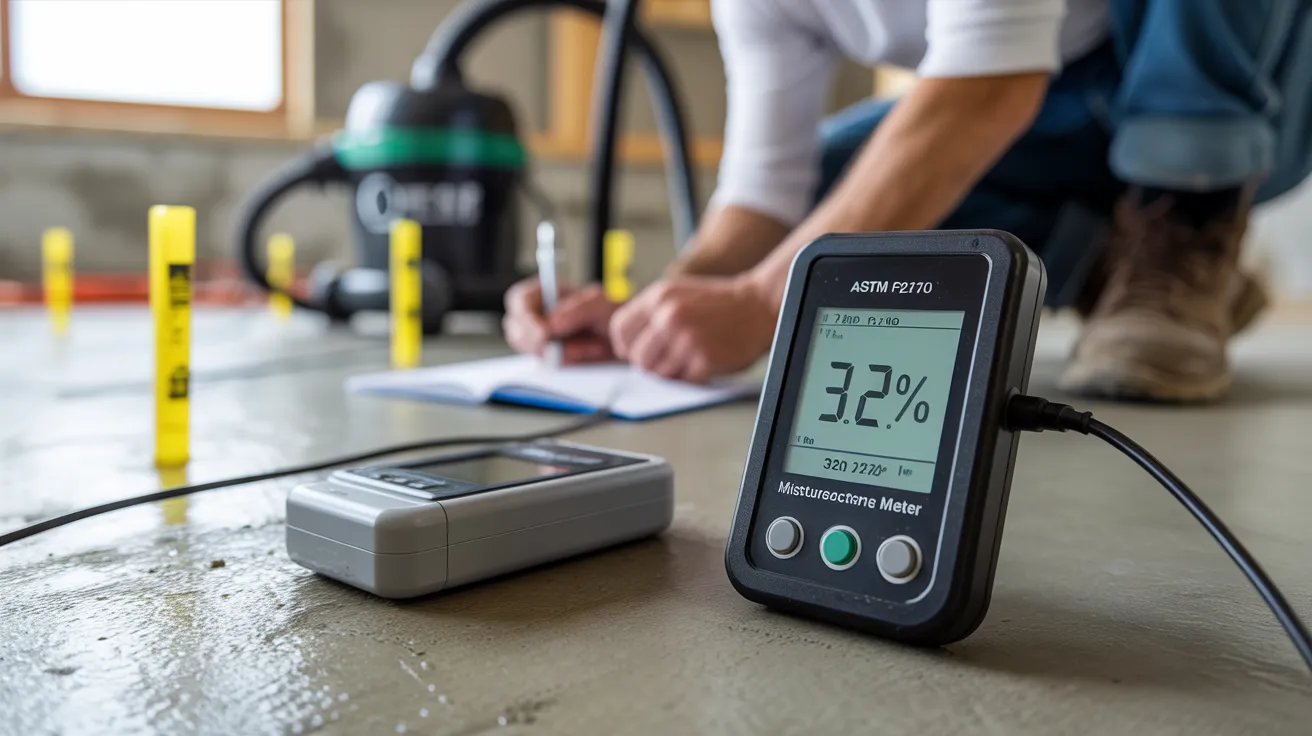

We begin with thorough pre-installation site prep, including substrate assessment, moisture testing, surface evening, and crack mitigation according to TCNA and manufacturer guidelines. Next, we create layout control lines, maintain uniform grout joints, and limit lippage within ANSI A108 specifications utilizing calibrated spacers and leveling systems. Throughout the process, we carefully document products, cure times, and adhesion tests to guarantee your project complies with code and warranty specifications.

Preparing Your Site for Installation

Setting up for success begins with rigorous site preparation that adheres to code and manufacturer specifications. Start by completing a documented substrate assessment: verify structural load capacity, flatness tolerances (usually 1/8" in 10'), and deflection limits according to TCNA/ANSI. Identify cracks, hollow spots, contaminants, and incompatible coatings. Then, perform moisture testing-ASTM F2170 or F1869 as applicable-and establish moisture mitigation when readings surpass the tile system's limits. Address plane and level using appropriate patching compounds, then abrade, clean, and vacuum to create a bondable surface.

You isolate movement joints according to EJ171, handle passageways and thresholds, and confirm heating mat installations meet specified depth and listing criteria. In conclusion, prepare materials, verify lot consistency, condition as needed, and verify ambient conditions-temperature, humidity, and ventilation-fall within required specifications.

Quality Tiling Standards

Execute the install according to TCNA, ANSI A108/A118/A136, and manufacturer requirements, recording every phase for traceability. Confirm substrate evenness within precision tolerances, proper plane, and necessary slope to drain. Pick mortars and membranes per exposure, deflection, and bond criteria, then key-in and comb notches in one direction to achieve required coverage. Install tiles with minimum lippage, confirm joint alignment, and keep movement joints following EJ171.

You implement grout standards depending on joint width, traffic, and chemical exposure, then blend, install, and shape within acceptable temperature and humidity ranges. You clear away remnants while preserving surface integrity and cure per product data. You execute adhesion testing, coverage verification, and layout evaluation, generating visual evidence and documentation that prove compliance and assure lasting performance.

Long-Term Value, Durability, and Maintenance

While design influences choices, durability, care requirements, and lifetime expenses define actual value. You need assemblies that withstand wear, water exposure, and temperature changes without early breakdown. Choose tile with established resilience and a PEI or DCOF value matching the intended use. For heavily trafficked areas, we suggest porcelain and straight edges where narrow joints are needed. Focus on grout durability with modified or epoxy grout compounds, suited to environmental conditions and maintenance plans. Apply industry-standard adhesives and control joints as specified by TCNA EJ171 to minimize fractures. Seal natural stone per manufacturer instructions; confirm cleaner compatibility. Arrange routine examination of sealants, transitions, and flexible joints. With correct base preparation, water barriers, and air circulation, you'll reduce callbacks, extend service life, and protect long-term value.

Budgeting, Quotes, and Project Timelines

Prior to starting construction, obtain a detailed written proposal that aligns work scope, financial plan, and timing. Include line item details for materials, labor, substrate preparation, moisture barriers, and finishing details. Request square footage calculations, tile arrangement diagrams, grout specifications, control joint positioning, and ANSI/TCNA standards for water-exposed zones. Clearly define removal methods, debris removal, and dust control measures.

Create a reasonable budget with get more info a ten to fifteen percent contingency buffer for unforeseen material problems or building regulation upgrades. Request unit rates for add/alternate items so adjustments stay visible. Verify lead times for tile, membranes, trims, and specialty drains to avoid timeline delays.

Define project milestones: procurement, demolition, substrate correction, dry-fit, installation, cure times, and final sealant. Factor in permit processing times and highlight inspection requirements that could delay progress. Structure payment schedule around achievement points instead of fixed dates.

How to Assess and Find the Ideal Service Provider

Although an offer looks promising, diligently vet the contractor with the same level of scrutiny you dedicate to specs and codes. Begin your contractor assessment by verifying licensing status through Ontario's regulatory bodies and WSIB coverage. Be certain to validate liability insurance and ask for a written scope that aligns with TTMAC standards, covering substrate preperation and waterproofing requirements.

Create detailed interview inquiries addressing: who executes the work, dimensional requirements, control joints, grouting materials, setting durations, dust control, and area safeguarding. Ask for a detailed schedule with key dates and modification procedures. Request a written warranty.

Conduct thorough reference reviews with previous clients and suppliers; validate schedule adherence, workmanship, and problem handling. Examine a current jobsite for safety protocols and organization. Evaluate bids on equal terms on supplies, setup, and final touches. Select proven expertise over cheapest quote.

FAQ

What Are Your Options for Eco-Friendly and Recycled Tiles and Adhesives

Indeed, we offer eco-friendly tile options and low-VOC adhesives. You'll get eco-friendly products, such as repurposed ceramics, glass, and porcelain tiles, sourced from certified manufacturers. We implement eco-safe, water-based, and GREENGUARD/LEED-verified adhesives and grouting materials. You'll receive information about traction ratings, emission limits, and long-term expenses. We verify EPDs and HPDs, confirm recycled content, and guarantee code-compliant installation methods. You'll reduce waste using detailed planning, sustainable waste management, and thinset recycling initiatives.

Can You Integrate Radiant Floor Heating With Tile Installations?

Yes, it's possible to integrate radiant floor heating with tile installations. We evaluate subfloor requirements, insulation requirements, and system demands, then specify Electric heating mats for specific areas or Hydronic solutions for complete home heating. We adhere to electrical and plumbing codes, place decoupling membranes, and set thin-set coverage to manufacturer specs. We check sensor placement, expansion joints, and GFCI protection. Lastly, we initiate system operation, document warranties, and arrange a systematic warming process to protect grout and tile.

What Guarantees and Warranties Are Available for Workmanship and Materials

We provide a Lifetime warranty on qualifying materials guaranteed by manufacturers and a five-year Labor warranty on our workmanship. We implement installations in accordance with TCNA standards and local building codes, documenting substrates, mortar systems, membranes, and grout specifications. We register product warranties, issue written warranty certificates, and carry out post-install inspections. Should workmanship issues occur, we'll address the issues-correct or change-at no cost. Warranty does not cover damage from misuse, building shifts, water damage, or improper care.

How Are Unexpected Structural Issues Managed During Tiling Projects

Work is paused to record observations and update you on project parameters, expenses, and schedules. Safety measures are implemented to contain compromised sections and facilitate structural inspections. Building permits are managed while providing detailed plans and adhering to construction regulations. Upon your approval, damaged substrates are addressed, damaged structural elements are restored, and effective water protection, vapor barriers, and crack prevention systems are placed. Change orders are updated, debris management continues, and installation continues only after approval is received and structural stability is verified.

Do You Have Insurance for Liability and Workers' Compensation in Ontario?

It's important to verify that we maintain active liability coverage and workers' compensation in Ontario. We can furnish proof of insurance with you listed as certificate holder, showing policy limits, copyright details, and effective dates. Our WSIB clearance verifies coverage and good standing. We follow OHSA requirements, carry out site-specific hazard assessments, and implement PPE and safe-work procedures. Request updated documents prior to project start and during major phases to make certain ongoing regulatory compliance.

Conclusion

When all is said and done, you're choosing verified performance, not mere assurances. The belief that "all tile contractors are equal" breaks down under actual use-much like grout that hasn't properly cured. When you choose certified Mississauga experts, you obtain proper code-following prep work, established ANSI/TCNA techniques, verified protection, and progress you can follow. Your surfaces resist moisture, movement, and aging because crucial components-expansion joints, surface flatness, waterproofing-are essential requirements. Require clear quotations, mockups, and verification steps. You don't take chances with completed work; you specify performance requirements, and you confirm the results.